Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

|

|

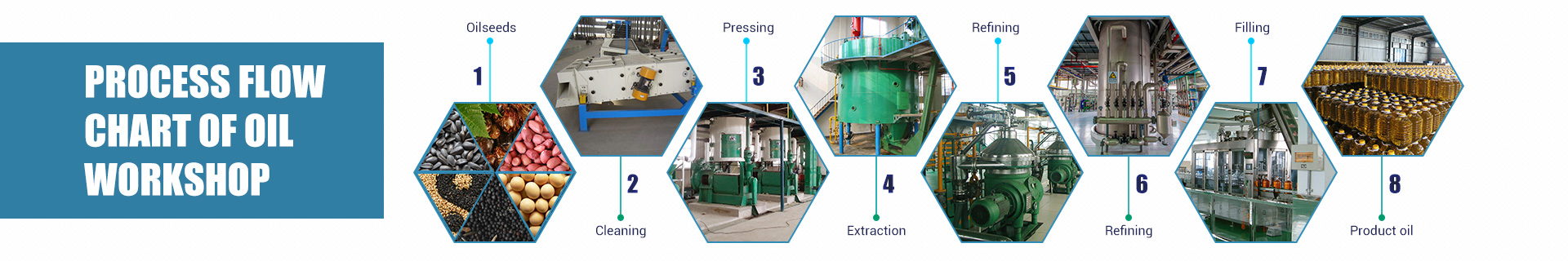

Cooking oil screw press machine

Cooking oil screw press machine working principle:

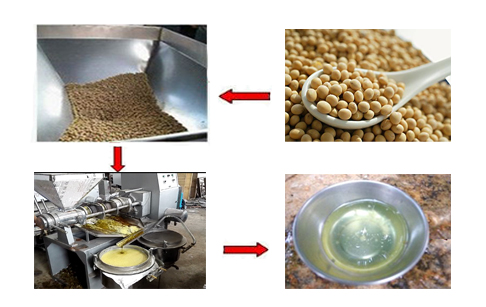

Cooking oil screw press work is due to the rotating screw axis in the bore in squeeze boost, make the press material continuously forward, at the same time, due to squeezer spiral lead to shorten or root diameter increase gradually, make the pressing chamber volume shrinking and squeeze is continuous squeezing action.

Features of cooking oil screw press machine:

Cooking oil screw press is a use of the helical axis of rotation when pressed cages promote material embryo, while squeezed into the cake, while extracting oil continuous oil extraction equipment. Compared with the "hydraulic machine" features are: continuous production, stand-alone processing capacity; able to adapt to a variety of materials; dynamic extrusion press, friction and heat, squeeze a short time, high oil yield; cake thin friable; low intensity operations . The disadvantage is the relatively large energy consumption; easy consumption and more high-maintenance machine failure; greater impact, such as hot cakes.

|  |

Cooking oil press machine

Factors of screw oil crushing mechanism:

1,According to the squeezed juice into the material requirements to determine embryo moisture and temperature, a press high temperature (125-130 ℃), low moisture (1.5% -2.5%); the use of pre-press temperature(105-120 ℃), moisture (3.5% -7.0%); cold-pressed using low temperature (25-60 ℃), high moisture (3.0% -8.0%).

2,Adjust and maintain sufficient press time, pressing time depends on the screw shaft speed and the cake thickness of two factors: ① screw shaft speed is generally fixed, maintain normal press time 120-200s;② adjust the cake ring gap can change the cake thickness. General press cake thickness control in 5-10mm, pre-press for 12-17mm.

3, The impact of cage bars shim thickness.

4,Effect of pressing chamber temperature, when the water is too low or containing shell is too big, the cake is too thin and other factors caused pressing chamber pressure, high oil cake fat coke, smoke or even "Shelling" phenomenon, that the pressing chamber temperature is too high, must be cooled.

Soya oil press machine

Classification of cooking oil screw press machine:

Cooking oil screw press machine is usually in accordance with the pressing stage into a level, two level and multilevel press press press press press bore; rotary shaft into the number of single screw and twin - screw press; by end use can be divided into a press, pre press, cold press and special press; according to production capacity also can be called type medium sized and small. No matter what models, which have the same working principle, structure includes a feed device, pressing chamber, adjustable cake mechanism, driving system and frame etc.