Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

The purpose of cooking oil refining is to remove the impurities, keep grease biological properties, retain or extract useful substances. In fact, not all of refining to remove impurities, but selectively purify. According to the composition and properties of crude oil in the magazine can be divided into three categories:

1, the insoluble solid impurities, such as sand, meal powder, fiber, clay, catalyst and the like.

2, glue insoluble impurities, such as FFA, sterols, vitamin E, pigments, gossypol and the like.

3, volatiles, such as water, alcohols, hydrocarbon solvents, odor material.

Cooking oil refining plant

Cooking oil refining principles:

1, to maximize the refining rate, reduce the consumption of refining. Strive to improve the process, the use of advanced technology and reliable equipment. To achieve the highest oil yield. Such as salad oil production by physical refining instead of chemical refining; note that every process to reduce emissions of the reactants.

2, depending on the nature of crude oil, oil products, composition and size indicators, to determine the most reasonable step combinations.

3, the process is simple and reasonable, less equipment and advanced production process of mechanization, continuous, high degree of automation, low labor intensity. Such as improved physical refining process using new SiO? adsorbent will closely degumming, bleaching and deacidification.

4, processes and process equipment configuration adaptability stronger.

Why the removal of impurities in the oil?

Most of the impurities for oil quality and storage safety disadvantage. Such as water not only affects the transparency of oil and grease will lead to hydrolysis rancidity; insoluble impurities and acidic substances are contributing factor to grease deterioration;

FFA affect the flavor, promote the deterioration; phospholipids make Grease muddy, but when heated to produce a black precipitate, blistering, hair waiting;

Various pigments directly affect oil color, and some will promote fat rancidity; gum, sulfur, phosphorus compounds and soap, heavy metal salts such as the existence of subsequent processes such as acid stripping off difficulties hydrogenation catalyst poisoning;

FFA and water to make a transesterification catalyst to reduce the activity; a lot of metal ions is not only pro-oxidant oil again at high temperatures, but also directly harmful.

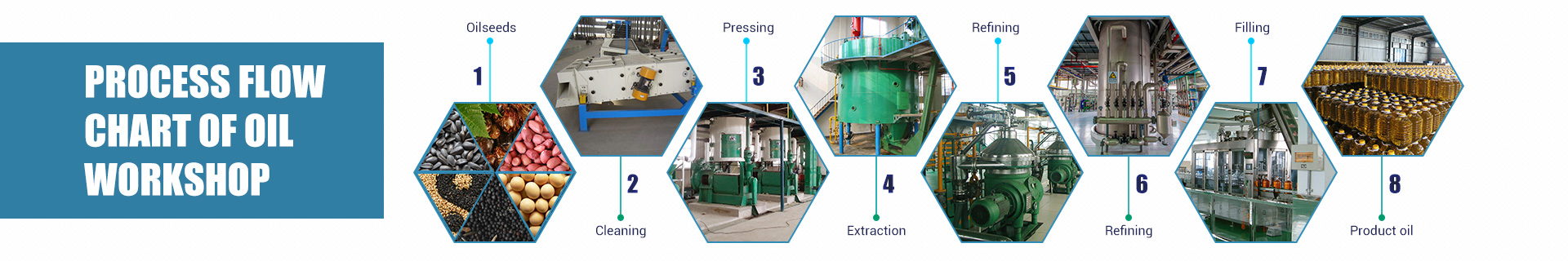

The main cooking oil refining processes:

1, remove the hair oil insoluble impurities, using sedimentation, filtration, centrifugation, and other physical methods;

2, degumming, removal of crude oil phospholipids, myxoid stroma, etc., the general hydration, acid or enzymatic degumming refining;

3, alkali refining;

4, washed with water, wash the residue in refining the soapstock with water soluble impurities;

5, drying, heating, vacuum drying, removal of refined oil in the water;

6, decolorization using activated clay,to remove the oil in a variety of pigment, resin and oxides;

7, deodorizing or physical refining;

8, dewaxing or degreasing, mainly freezing winter of crystal or crystal fractionation to remove oil waxes;

9, filter or fine filter.