Tel/WhatsApp

Tel/WhatsApp

Main function of small scale tyre recycling plant

Small scale tyre recycling plant is also called mini pyrolysis machine which can recycle waste tyres mainly from car repair shops into fuel oil, carbon black, steel wire and combustible gas according to the principle of pyrolysis.

This small scale tyre recycling plant mainly used to test the overall quality and operability of the equipment, and some customers also used to test the yield of raw materials. If the customer wants to do the tire pyrolysis project, he can buy a small scale tyre recycling plant at a lower price to test the effect of the project, and then start the large production for 10T or 12T tyre recycling plant.

Small scale tyre recycling plant

Small scale tyre recycling plant

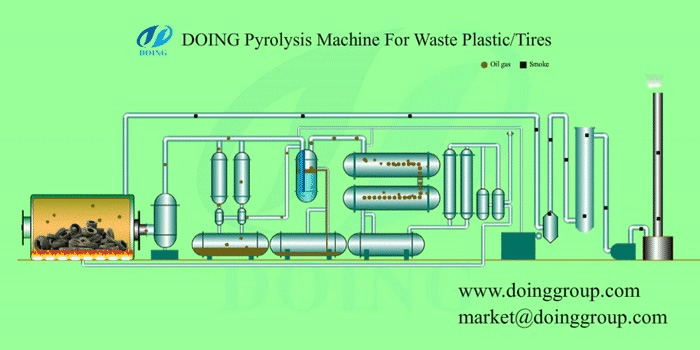

Main workflow of DOING Machinery's small scale tyre recycling plant

1. Feeding waste tyres

Feed the waste tyres into the pyrolysis reactor via an automatic pusher.

2. Heating pyrolysis reactor

One of coal, gas, wood, etc. can be used as fuel to heat the reactor at the bottom. The pyrolysis reactor of DOING Company is a rotary design, which rotates uniformly while heating, so that the raw materials can be uniformly heated. When the temperature reaches a certain level, the waste tyres will be pyrolyzed into oil gas.

3. Cooling down the oil gas

As the heating progresses, the oil gas generated in the pyrolysis reactor will enter the condensing system along with the pipeline. Cooling by circulating cooling water in the condenser, some of the oil gas can be cooled into liquid and collected into the oil tank. The left oil gas will go to the tail gas cleaning and odor removal system.

4. Tail gas treatment

Tail gas cleaning and odor removal system can remove fumes or odors among the left oil gas, then what's left is a portion of the gas that can't condense. This non-condensiable gas will be used to heat pyrolysis reactor.

5. Carbon black and steel wire discharge

When the pyrolysis reactor is cooled to below 40 degrees, discharge the carbon black and steel wire from the reactor.

Main workflow of small scale tyre recycling plant

Main workflow of small scale tyre recycling plant

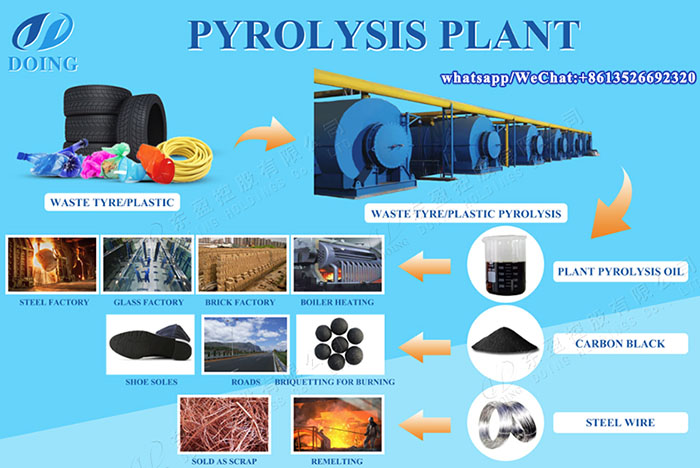

Specific uses of final products from small scale tyre recycling plant

The obtained final products from small scale tyre recycling plant have widely uses in our daily life. As shown in the figure below.

Specific uses of final products from small scale tyre recycling plant

Specific uses of final products from small scale tyre recycling plant

Fuel oil usage

Mainly used in iron and steel plants, boiler heating, heavy oil generators, and cement plants, etc.

Carbon black usage

It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

Steel wire usage

Steel wire is mainly used for waste recycling and recasting.

Benefits of running tyre recycling plant

What are the benefits of running tyre recycling plant?We can know from the above product usage that the gains are mainly due to fuel oil, carbon black, and steel wires that are cracked out of tyre recycling plant.

Of course, the small scale tyre recycling plant handling capacity is limited, and the profit is also limited. If you want to get a higher profit, you can choose our 10TPD or 12TPD tyre recycling plant. The following is the profit analysis based on the 10TPD tyre recycling plant.

| Tyre Recycling Plant Profit Analysis (Take a 10TPD machine as an example) | |

| Operating cost/day | |

| Used tyres | 10 tons * 80 US dollars/ton = 800 US dollars |

| Heating fuel (Choose one of the fuels) | 1. Coal: 0.4 tons * 125 US dollars/ton = 50 US dollars; 2. Fuel: 0.4 tons * $490/ton = $196; 3. Diesel: 0.3 tons * $740/ton = $222; 4. Natural gas: 150m3 * 0.35 USD/m3 = 52.5 USD |

| Power consumption | 20Kw/h = 30 U.S. dollars |

| Water consumption | Water is recycled and almost no consumption |

| Workers | 3 persons * 23 U.S. dollars = $ 69 |

| Earnings/day | |

| Fuel oil | 4 tons * $490/ton = $1960 |

| Carbon black | 3 tons: (1) Direct selling, *60 US dollars/ton = 180 US dollars |

| Steel wire | 1.5 tons * 120 US dollars/ton = 180 US dollars |

| Profit/day (calculated on the basis of burning fuel oil and carbon black) | $1,275/day |

The specific advantages of tyre recycling plant

Of course, this kind of profit can be attributed to the high oil output rate of DOING Machinery's tyre recycling plant, and the high oil output rate is closely related to the following advantages of the tyre recycling plant.

1. The pyrolysis reactor adopts Q245R standard boiler plate which thickness is 16mm and can withstand high temperature and high pressure.

2. The pyrolysis reactor adopts a unique 3-step welding process , which is not easy to crack and has a long service life.

3. External insulation system is installed outside the pyrolysis reactor to avoid heat loss and save energy.

4. The pinion rotating device of pyrolysis reactor has a low power and does not directly contact the reaction vessel. It has less heat transfer and is not easily deformed.

5. The whole set tyre recycling plant is designed with safety devices, such as oil-water separators, water seals, vacuum devices. Water seals can purify oil gas, tail gas, and prevent oil gas or tail gas backflow. Vacuum devices can provide negative pressure to drain oil gas in the pyrolysis reactor when a batch of operations is completed.

Pyrolysis reactor of small scale tyre recycling plant

Pyrolysis reactor of small scale tyre recycling plant

In addition to the above, the unique advantage of such small scale tyre recycling plant is its low cost, easy transportation and simple installation.

Low cost

Of course, compared with 10 tons and 12 tons tyre recycling plant, the price of small scale tyre recycling plant is lower, but they have the same function, can also carry out normal production operation, but the processing capacity is small.

Easy transportion

As our small scale tyre recycling plant is small in size and weight, it is easy to transport. For example, 500 kg small scale tyre recycling plant can be transported with only one high cabinet.

500 kg small scale tyre recycling plant sent to Chile

500 kg small scale tyre recycling plant sent to Chile

Simple installation

For this kind of small scale tyre recycling plant, we design the frame type. After receiving the equipment, the customer only needs simple assembly and can use it directly, which also saves time for customer.

Get in touch with us for a free quote and we have a professional project manager to help you design the project plan, if necessary, we can also provide the project declaration materials. We sincerely look forward to cooperating with you.