Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

DOING Company's small scale cooking oil manufacturing machine with a packaging line is very popular among customers, because of its low investment and good effect. If you want to set up a small scale cooking oil manufacturing plant, the small scale cooking oil manufacturing machine with a packaging line is your best choice.

DOING small scale cooking oil manufacturing machine with a packaging line

DOING small scale cooking oil manufacturing machine with a packaging line

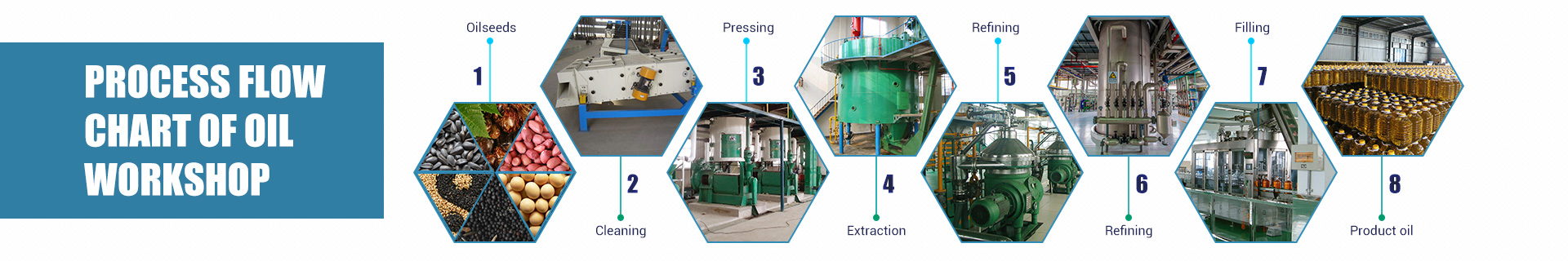

As the above picture shows, the small scale cooking oil manufacturing machine with a packaging line includes small drum roaster, screw conveyor, screw oil presser, small plate filter, small cooking oil refining machine and small cooking oil packaging machine.

The main functions of each machine:

1. Small drum roaster: Adjust the temperature and moisture of the oil seeds, making them more easily be pressed and improve the oil yield rate.

2. Screw conveyor: Transport the oil seeds from one machine to another machine.

3. Screw oil presser: Using the principle of physical extrusion to get the oil from oil seeds.

4. Small plate filter: Filter the crude oil to remove the impurities out of oil.

5. Small cooking oil refining machine: Through degumming, deacidification, decolorization and deodorization four processes to remove gum, free fatty acid, some pigments and bad smells. Then the crude oil will become refined cooking oil.

DOING small cooking oil refining machine

DOING small cooking oil refining machine

6. Small cooking oil packaging machine: Fill the cooking oil into bottles or bags. The capacity of cooking oil packaging bottle or bag can be customized based on customers' needs.

The input capacity of the small scale cooking oil manufacturing machine with a packaging line:

It can be customized into 1-10 tons per day processing capacity. The machines used in small scale cooking oil manufacturing machine with a packaging line will be designed and matched by our engineers based on customers' real condition. So you need tell us what oil seeds you want to process and how many tons oil seeds you want to process per day.

The feature of the small scale cooking oil manufacturing machine with a packaging line:

1. Can be used to process different kinds of oil seeds, such as soybean, groundnut, sunflower, sesame, rapeseed, cottonseed, rice bran...

The oil seeds can be processed by the small scale cooking oil manufacturing machine

The oil seeds can be processed by the small scale cooking oil manufacturing machine

2. Low investment, the return of funds more quickly.

3. Small footprint and easy operation.

4. The final cooking oil quality is qualified the national standards.

5. Professional manufacturer production, making sure the quality of the machines and having better after-sale services.

Henan Doing Company sincerely wants to cooperate with you. Looking forward to receiving your enquiry!