Tel/WhatsApp

Tel/WhatsApp

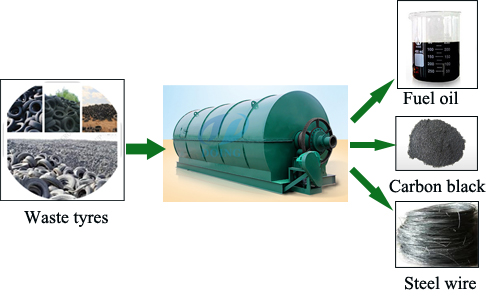

Scrap tyre to oil production plant machinery

Scrap tyre to oil production plant machinery adopts the latest pyrolysis technology can be convert waste tyre to oil ,carbon black and steel wire .The main advatage of scrap tyre to oil production plant is zero emission ,high efficiency .Scrap tyre to oil production plant machinery not only can solve the problem of waste tyre pollution ,but also can bring substantial benefits for you.

Scrap tyre to oil production plant machinery working process

In the waste tyre pyrolysis process, the waste tyres will firstly be put into the reactor.

Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically. When the temperature fall to 100℃, workers could open the door of the reactor to discharge the rest steel wire.

Lastly, the released gas can achieve national emission standard through the dedusting system。

After the whole pyrolysis process of tyres is completed, the final products such as tyre oil, carbon black and steel wire can be sold directly or further processed into new products. Anyway, you will benefit a lot from them.

Scrap tyre to oil production plant machinery advantage

1. Safety.

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protecting.

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

3. Energy saving.

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst

chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

4. High degree of automatic.

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

Scrap tyre to oil production plant machinery final product application

Fuel oil

Pyrolysis oil :- 40 to 45%

Carbon black:- 30 to 35%

Steel Wire:- 10 to 15% ( Depend on Type Of Tyre being use )

Pyrolysis Gas:- About 10 %