Tel/WhatsApp

Tel/WhatsApp

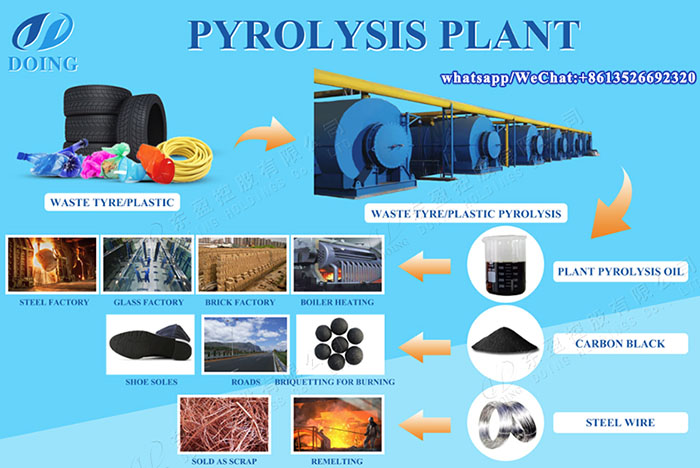

Rubber tyre pyrolysis machine can convert waste rubber tyre into useful resources, such as fuel oil, carbon black, steel wire. The rubber tyre oil can be used as industrial fuel materials for burning, or further refined into diesel by oil distillation machine. The carbon black can be used for making construction bricks with clay or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

Final products and their applications from rubber tyre pyrolysis machine

Final products and their applications from rubber tyre pyrolysis machine

The main processing flow of rubber tyre pyrolysis machine

Rubber tire→ automatic feed → heating & pyrolysis→ oil-water separation → cooling liquid → carbon black emission → carbon black processing → crude rubber tyre oil → flammable gas recovery → flammable gas combustion → desulfuration removal.

The main processing flow of rubber tyre pyrolysis machine

The main processing flow of rubber tyre pyrolysis machine

Unique advantages of rubber tyre pyrolysis machine

1. Safety

On the security side, our focus is on the details. We have design some safe devices such as the pressure gauge, alarming ring, safety valve. In addition , we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protection

Some polluting gases are produced when rubber tyres are pyrolyzed and when fuel is burned. Aiming at the pollution gas produced in rubber tyre pyrolysis process, we designed the tail gas deodorization device and desulfurization & purification tower. After being treated by these devices, the final gas can be discharged environmentally.

Environmental protection configuration of rubber tyre pyrolysis machine

Environmental protection configuration of rubber tyre pyrolysis machine

3. Energy saving

We can use the combustible gas generated in the reactor to heat the reactor, which can save some fuel.We also designed a negative pressure device, which can use the negative pressure to completely discharge the oil gas in the reactor after the reaction, speeding up the cooling of the reactor, thus reducing the waste of oil gas and making the operation of the rubber tyre pyrolysis machine safer.

4. High degree of automatic

We have many automatically devices such as: auto-feeder, carbon black screw conveyor, oil pumping automatic,automatic pressure relief device and so on.

In addition, we also design a fully automatic rubber tyre pyrolysis machine, which is controlled by PLC control system. This machine can save manpower, and can achieve automatic operation.

Carbon black screw conveyor

Carbon black screw conveyor

Technical parameter of rubber tyre pyrolysis machine

| Technical parameter of rubber tyre pyrolysis machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste rubber ,waste tyre | Waste rubber ,waste tyre | Waste rubber ,waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

Prepared by customer about rubber tyre pyrolysis machine

| Prepared by customer about rubber tyre pyrolysis machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

As a professional supplier of rubber tyre pyrolysis machine, DOING also provides a full set of after-sales services such as installation, equipment debugging and operation training, etc. If you are interested in our rubber tyre pyrolysis machine, welcome to contact us directly.